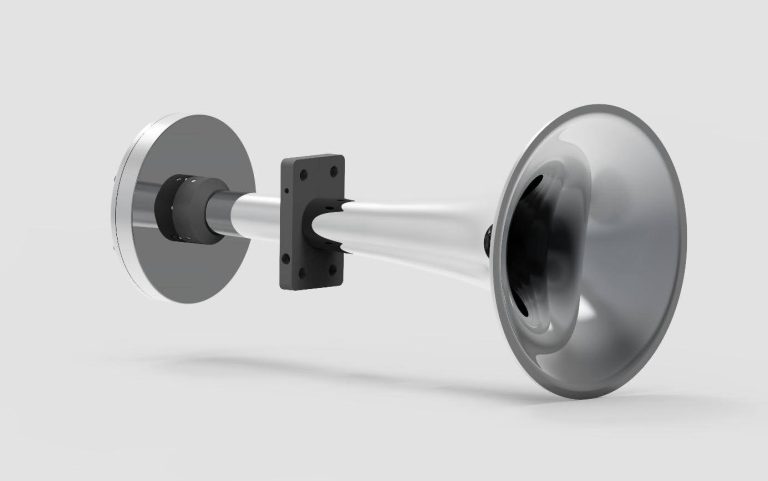

Model: USER SONIC

Product Name: Sonic Sootblower – High-Frequency Acoustic Cleaning System

Manufacturer: USER MÜHENDİSLİK

Application Area: Boilers, heat exchangers, flue gas ducts, furnace walls, and high-temperature areas with particulate accumulation

1. GENERAL DESCRIPTION

The SONIC-SB-170 model is a high-performance acoustic sootblower operating at 170 Hz and capable of generating up to 153 dB sound pressure. It provides contactless cleaning of ash and dust deposits in high-temperature environments using sound waves, eliminating the need for mechanical impact.

The system is designed with user-friendly automation infrastructure and operates with PLC-based control, integrated timer, SCADA compatibility, and an intuitive touch-screen interface. Cleaning cycles can be pre-programmed and easily integrated with external systems.

2. OPERATING PRINCIPLE

The system is supplied with compressed air via a 3/4” air connection at a pressure range of 0.4 – 0.6 MPa. The acoustic diaphragm, driven by this pressure, generates sinusoidal sound waves at 170 Hz.

These sound waves resonate with the natural frequency of the particulate layers, detaching the deposits from the surface.

The cleaning cycle is automatically managed via a PLC-based control unit. With full SCADA compatibility, the system allows remote monitoring and operation.

The touch-screen user interface enables easy configuration of parameters such as frequency, duration, and cleaning intervals.

3. TECHNICAL SPECIFICATIONS

Technical Parameter | Value |

|---|---|

Operating Frequency | 170 Hz (at 20°C ambient temperature) |

Sound Pressure Level (at 1 meter) | 150 – 153 dB |

Feeding Pressure (during signal) | 0.4 – 0.6 MPa (4 – 6 bar) (58 – 87 psi) |

Air Consumption (during signal) | 70 – 108 L/s (2.47 – 3.8 cfs) |

Cooling Air Consumption | 1 – 2.5 L/s (0.04 – 0.09 cfs) |

Max Temp. Resistance – Bell Piece | 1000°C (1832°F) |

Max Temp. Resistance – Diaphragm Housing | 500°C (932°F) |

Solenoid Valve Temp. Resistance | 80°C (176°F) |

Air Connection | 3/4” threaded pipe |

Air Supply Piping | Minimum 1”, max 6 m pipeline per emitter |

Device Weight | Approx. 45 kg (99.2 lbs) |

Solenoid Valve Voltage | 24V DC (230V AC optional) |

Control System | PLC-based, integrated timer, SCADA compatible |

User Interface | Touchscreen – adjustable operational parameters |

4. ADVANTAGES

- ✅ Continuous cleaning at high temperatures

- ✅ Non-contact operation – no surface erosion

- ✅ Automatic scheduling and remote control (PLC + SCADA)

- ✅ Low maintenance requirements, long service life

- ✅ User-friendly interface – touch-screen operation

- ✅ Suitable for harsh industrial applications: power plants, cement, biomass, etc.

Note: For project-specific system configurations, resonance frequency simulations, 3D layout plans, and engineering support, please contact USER MÜHENDİSLİK.