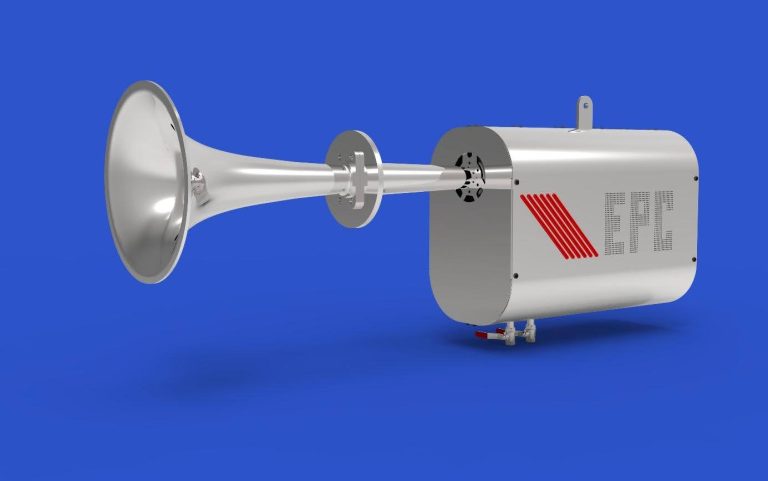

Model: EPC-170

Product Name: Explosion Pulse Cleaning (EPC) System

Manufacturer: USER MÜHENDİSLİK

Application Area: Removal of slag and ash from boilers, tube bundles, economizers, and other high-temperature surfaces

1. GENERAL DESCRIPTION

The EPC (Explosion Pulse Cleaning) system is an advanced cleaning technology developed to remove stubborn slag and ash deposits that adhere tightly to internal surfaces. It works by producing high-intensity shock waves and sound pressure of up to 170 dB, with 4–10 pulses per second and a cleaning range up to 10 meters. EPC operates efficiently even in extreme environments up to 1500°C.

2. OPERATING PRINCIPLE

Two different gases (compressed air and fuel gas) pass through a series of measurement and control valves and are mixed in a dedicated mixing chamber at an optimal ratio. This mixture is:

- Ignited by high-voltage spark plugs within milliseconds,

- Rapidly expands and exits through the nozzle at Mach ≥ 1,

- Producing a shock wave that is directed into the boiler volume to dislodge deposits.

Pulse Interval: 5–15 seconds

Pulse Frequency: 4–10 pulses/second (6–90 bursts per cycle)

3. TECHNICAL SPECIFICATIONS

Parameter | Value |

|---|---|

Sound Pressure Level | >170 dB (C-weighted peak) |

Operation Frequency | 4–10 pulses per second |

Effective Cleaning Range | Up to 10 meters |

Max Flue Gas Temperature | 1500°C |

Gas Consumption | ~0.4 g/pulse, ~4 g/s |

Compressed Air Consumption | Approx. 50 Ndm³/s (during operation) |

Ignition System | Spark plug (millisecond trigger timing) |

Control System | PLC with touchscreen interface |

Gas Sources | Industrial air and fuel gas |

Mounting Type | Flanged / Direct integration to boiler walls |

Module Quantity | Varies depending on application area |

Automation | Fully programmable, remotely monitored |

4. MATERIAL SPECIFICATIONS

Component | Material |

|---|---|

Actuator | AISI 316 / |

Horn | AISI 316 / |

5.THERMAL & MECHANICAL EFFECTS

Thermal Effects

- Sudden pressure, temperature, and entropy fluctuations along shock wave path

- Induces thermal fatigue and weakens adhesion of slag and ash layers

- Layers separate due to stress from extreme thermal gradients

Mechanical Effects

- Shock waves create push-pull oscillation in air, inducing scrubbing effect on surfaces

- Sharp and narrow shock fronts generate high shear forces

- Pressure fluctuations weaken molecular bonds in deposit layers

- Reflections between tubes amplify internal damage in stubborn deposits

- Energy penetrates deep into boiler via acoustic reflections

6. CLEANING PERFORMANCE

Deposit Type | Cleaning Efficiency |

|---|---|

Non-sintered ash | ✅ High |

Sintered slag | ✅ High |

Resin/sticky deposits | ⚠️ Limited |

Note: Cleaning effectiveness depends on deposit type, geometry, and system configuration.

7. KEY ADVANTAGES

- ✅ Online Cleaning: Operates while system is running – no shutdown required

- ✅ Fully Automated: Operates on programmable PLC cycles

- ✅ Wide Area Impact: Acoustic wave penetrates deep and inaccessible regions

- ✅ Non-destructive: No corrosion, erosion, or mechanical abrasion

- ✅ Compact Design: Space-efficient, easy to install

- ✅ Custom Engineering: Tailored EPC design based on field parameters

8. PROJECT DESIGN & DELIVERY

Each EPC system is designed by USER MÜHENDİSLİK based on the following parameters:

- Surface dimensions (height, width, depth)

- Flue gas temperature

- Particle type, density, and adhesion behavior

- Internal structure of the boiler or application environment

A fully engineered, tailor-made EPC configuration is provided for installation and commissioning.

NOTE:

This datasheet provides general technical specifications. For project-specific CAD drawings, acoustic simulations, installation diagrams, or performance studies, please contact USER MÜHENDİSLİK directly.