Model: UEBC-130

Product Name: User Explosion Boiler Cleaning (UEBC) System

Manufacturer: USER MÜHENDİSLİK

Application Area: Mitigation of slag accumulation in boilers, furnaces, and high-temperature process chambers

1. GENERAL DESCRIPTION

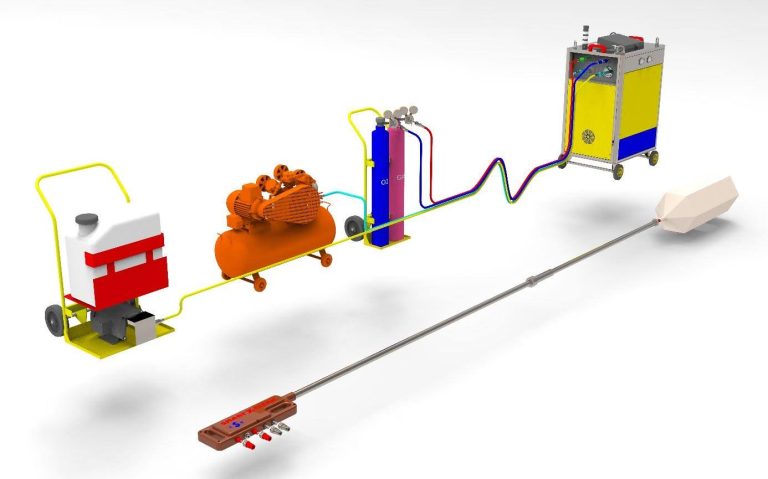

The UEBC system is an advanced cleaning technology that targets slag and particulate buildup in high-temperature industrial volumes using temporary and directional impact force. It allows intervention during operation and enables effective cleaning of specific areas without halting production. The system’s energy is transferred into the boiler through a specially configured carrier structure equipped with a variable-length probe (lens) assembly.

UEBC has been developed for use in a wide range of sectors including energy production, cement manufacturing, pulp and paper, biomass and waste incineration facilities.

2. OPERATING PRINCIPLE

The system operates on an internally guided energy conversion mechanism. A controlled release of structured energy within a defined volume generates a high-energy shock impulse into the surrounding space. This shock creates instantaneous mechanical stress on bonded surface deposits, causing slag disintegration and detachment.

The probe (lens) assembly used in the UEBC system is adjustable in length from 3 to 5 meters, allowing access to various depths inside the boiler. At the probe tip, four air-assisted atomizing nozzles are integrated. These nozzles not only provide cooling for the carrier but also protect the internal burst pouch during high-temperature operation, thereby extending the system’s operational lifespan.

Through these nozzles, water is transformed into approximately 300-micron atomized droplets with the help of compressed air. Upon contacting the hot surface, the droplets create localized vaporization and rapid thermal gradients, inducing thermal fatigue in the slag layer. This pre-conditioning weakens the slag structure, making the subsequent shock wave impact significantly more effective.

Note: The explosion mechanism is triggered remotely and securely by the operator. Unlike traditional mechanical impact systems, UEBC relies on acoustic resonance and pressure wave propagation for energy transfer.

3. TECHNICAL SPECIFICATIONS (Calculated & Verified)

Parameter | Value |

|---|---|

Pouch Volume | 110-130-150 liters |

Total Explosion Energy | ~1250 kJ (with 25 g methane) |

Peak Explosion Pressure | ~6.24 bar |

Estimated Peak Sound Pressure | ~209.9 dB |

Shock Wave Propagation Velocity | 860.94 m/s |

Mach Number (During Shock) | 2.58 (supersonic) |

Fuel Amount | 25 grams methane |

Oxygen Amount | 99.7 grams |

Cooling & Thermal Shock System | 4-nozzle air-assisted water atomization |

Probe Assembly (Lens) | Adjustable between 3–5 meters |

Atomized Droplet Size | 300 microns |

Application Depth | Adjustable, localized targeting |

Temperature Resistance | Up to 1200°C |

Usage Frequency | Repeatable during shift, per location |

System Mobility | Mobile, temporary setup under operation |

4. SYSTEM COMPONENTS

- Special mixture pouch (heat-resistant, single-use)

- Methane and oxygen supply lines

- Remotely controlled ignition system

- Adjustable probe (lens) structure

- Integrated 4-nozzle air-assisted atomization tip

- Operational handling and positioning mechanism

- Thermal insulation and cooling zone

- Safety valves and triggering components

5. ENGINEERING SUPPORT

NOTE:

For shock propagation simulations, 3D boiler layout planning, CAD technical drawings, and application engineering support, please contact USER MÜHENDİSLİK.

Engineering optimization is provided for project-specific aspects such as probe placement and explosion direction within your facility.