Model: UEPC-170

Product Name: User Explosion Pulse Cleaning (UEPC) System

Manufacturer: USER MÜHENDİSLİK

Application Area: Slag removal in superheaters of biomass power plants and high-temperature deposition zones

1. GENERAL DESCRIPTION

The UEPC system is an advanced, directional-pulse cleaning technology developed to remove stubborn slag accumulations in the superheater zones of biomass power plants. It operates online (in real-time) under flue gas temperatures up to 1500°C, using systematic, high-energy acoustic pulses to dislodge ash and slag from heat exchange surfaces.

2. OPERATING PRINCIPLE

The UEPC system operates via an internal energy conversion mechanism structured with controlled fluid dynamics. A precisely balanced mixture is triggered through synchronized activation, generating a directional acoustic wave that induces vibrational stress on slag layers. These stresses weaken adhesion and allow the deposits to detach from surfaces.

Note: The system regulates internal fluid characteristics and volumetric equilibrium through uniquely configured components. Synchronization between these elements is essential for system efficiency and performance.

3. TECHNICAL SPECIFICATIONS (Verified by Calculation)

Parameter | Value |

|---|---|

Sound Pressure Level | ~218.8 dB (peak value) |

Explosion Frequency | 1 pulse/hour |

Cleaning Radius | Spherical radius: 4.5 meters |

Exit Velocity | 860.94 m/s |

Exit Mach Number | 2.58 (supersonic) |

Explosion Energy | ~1000 kJ (with 20 g methane) |

Average Mixture Pressure | 17.5 bar |

Peak Explosion Pressure | ~122.5 bar (post ignition) |

Horn Exit Area | 0.0079 m² (DN100) |

Max Operating Temperature | Up to 1500°C |

Gas Consumption | 20 g methane |

Total Weight | ~100 kg |

Material | AISI 316 Stainless Steel |

Valves | 1/2” Zone 2 G2 ATEX certified |

Ignition System | High-energy long-type spark plug |

Control Unit | PLC with timer and SCADA integration |

Filling System | Automated via ex-proof pressure sensors |

User Interface | Touchscreen display |

Communication Protocols | PROFIBUS, Modbus, Ethernet (customizable) |

Mounting Options | Flanged + suspended (multi-orientation) |

Certifications | CE, ATEX |

4. EFFECT ON SLAG LAYERS

🛠 Mechanical Effect

- Shock waves break the molecular bonds within slag

- Detached slag disintegrates and falls from the surface

- Supersonic jet flow inside the horn ensures broad impact coverage

🌡 Thermal Shock Effect

- Sudden temperature differential occurs post-detonation

- Adhesion weakens, slag fractures and detaches

♻ Sustained Cleaning Efficiency

- 1 pulse per hour prevents solidification of layers

- Clean surfaces enhance heat transfer and overall efficiency

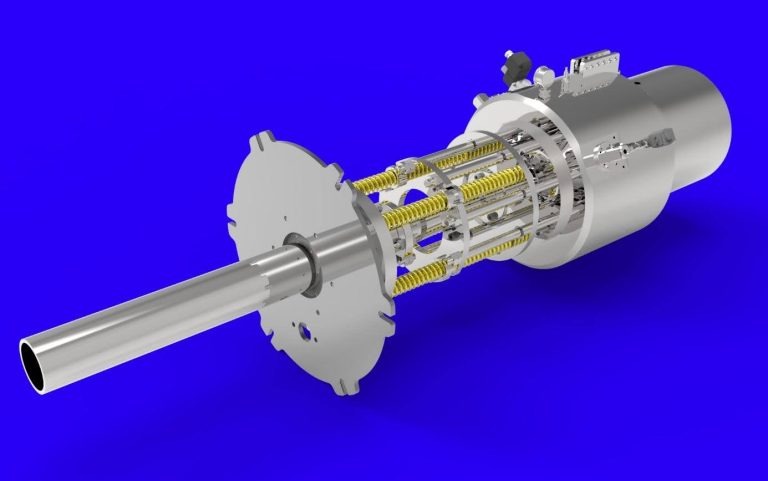

SYSTEM COMPONENTS

- Methane and oxygen tanks

- 4.3-liter mixing/explosion chamber

- Spark ignition system and control circuit

- Horn (DN100 outlet, 800 mm length)

- Ex-proof pressure and mixture sensors

- PLC + touchscreen HMI panel

- ATEX-certified valve assembly

- SCADA and industrial communication module (PROFIBUS, Modbus, Ethernet)

6. ADDITIONAL ENGINEERING SUPPORT

NOTE:

For acoustic simulations, 3D layout plans, CAD technical drawings, and engineering application support, please contact USER MÜHENDİSLİK.

Project-specific customization and placement optimization are available based on your boiler geometry, fuel properties, and slag behavior.