Faulty Application Example

Acoustic cleaners are used instead of steam soot blowers, especially in power plants. Thus, more efficiency and lower cost are provided.

The following factors are important for the effective use of sound physics.

- Project Engineering

- Application Engineering

- İnstallation and Commissioning process

If these procedures are not done correctly, the devices used in the system will not be effective properly. This will cause a waste of time and money.

As USER ENGINEERING, after the first contact with our customers, our field engineers start their work. These studies consist of 4 stages.

- Defining the system

- Collection of project and system information

- Simulation of data in software environment

- Installation according to the project

As a result of this study, it is very important for us to achieve the desired results in line with our past experiences.

The most important rule in this system working with sound physics; To know the system well and to have realistic information about its features. For this reason, your projects are handled using our previous installations, experience and engineering. Our project work is done accordingly.

The order below expresses the importance of 4 main rules.

- Defining The System ;

The information given to us by the company that produces a biomass burning boiler is as follows;

The product to be burned in the boiler; straw stalk and wood

Boiler inlet temperature; 750 °C

Boiler outlet temperature; 600 °C

Air flow rate; 65600 m3/h

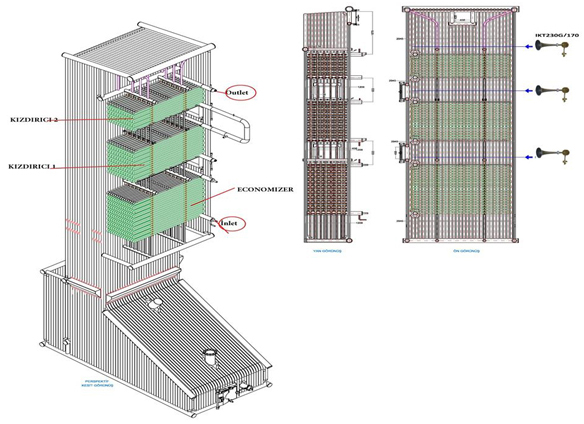

Regions; Economizer, superheater 1, superheater 2 - Collection of project and system information ;

DWG and sketches received from customer

- Simulation of data in software environment :

Our company chooses the model and frequency according to this information.

The software completes the positioning project work. In this project, a horn with IKT 230/170 hz frequency was selected to be used in every layer. The customer was send the installation projects of the products on the boiler, the method of installation, and the technical working information of the device. - Installation according to the project ;

Before the company delivered the boiler, our request for supervisor support was submitted for installation and commissioning.

Depending on the ash density formed in the boiler during installation, the working cycle is created through the automation of the system. Sonic Horn needs to be activated more frequent periods for very intense powdery mildew longer periods are used for less intense powdery mildew. After this process, the optimal working cycle for the boiler is completed and the project is delivered to the customer.

Results:

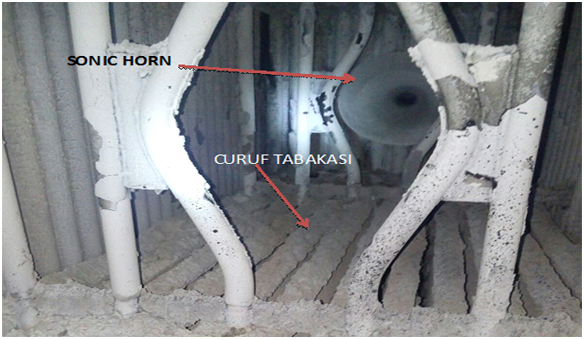

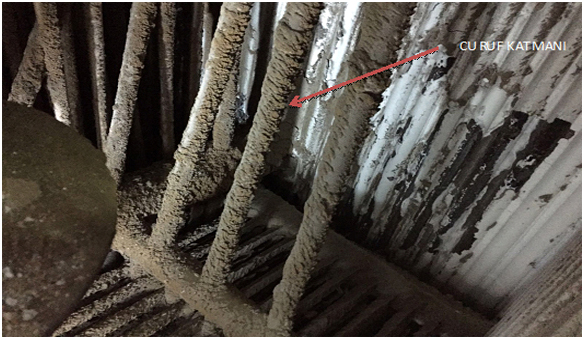

Unlike the previous information, cotton plate was used as fuel in the boiler commissioned. The inlet temperature of the superheater 1 and 2 regions has been measured as 1200 -1300 °C and the economizer has been as 1000 °C . The reasons like the internal temperature is too high, the flame height reaches the superheater 1 and the superheater 2 line during the combustion, the distance to the eco line is too low, the ash that is expected to form inside after combustion is slag, are causing adhesion on the heat transfer surfaces. As we know, especially in biofuels, combustion analyzes, melting temperatures must be predefined and the boiler design must be made in accordance with these analyzes. Especially in biofuel boilers, the success achieved in the previous application does not mean that it will be successful in the next. Because, in areas where the biomass to be burned will be burned, the soil, annual rainfall, and even the annual insolation can reach different melting degrees in the same type of fuel. Cotton silt in particular is the best example.

System Installation :

The boiler manufacturer company has completed the USER SONIC installation in accordance with the given project. In this application, the system was installed by the company. Support was given by us as a supervisor and the system was commissioned.

The assembly made by the company has not been approved by USER ENGINEERING. In our field study, it was determined that the preliminary preparations such as working pressure, air consumption, tank, which are required for the system, were specified in the project, but were not made. User Sonics should be run more frequently and with a longer activation time in difficult conditions. The system may require a reserve tank for 6 bar uninterrupted air pressure and 80 liters of air. In this study, 10-15 seconds of operation time was required with very short waiting times. However, the compressor could not meet these conditions, due to the lack of reserve tank.

In addition, it has been determined in the technical data of our product that it is exposed to high temperatures. Damage caused by heat has occurred on the product. The maximum temperature value for the bell part of our product is 1000 degrees, and the maximum temperature value for the wave generator is 500 degrees. The diaphragm in the wave generator exposed to high temperature is broken. The diaphragm seat is annealed due to the high temperature. It is not possible for a new diaphragm to work within this area.

The boiler did not operate at the desired efficiency. Due to contamination, The boiler was stopped every 4 days due to contamination and the heat transmission surfaces were cleaned.

As a result of these studies, it showed us that; Efficient running of sonic installations depends on a combination of factors such as correct selection, correct placement, correct setup and correct periods. As in the example, it is very important to know the calculations made in boiler design, to know the combustion characteristic of the fuel (melting temperature, etc.), and to create a design according to these features. It is undesirable for all steam blowers that the ash formed as a result of the combustion is at the melted level. In these cases, the best thing to do is to change the boiler design. However, when this cannot be achieved, steam soot blowers should be activated very often together with User Sonics.