User Hamster

User Hamster

User Hamster is a product developed to effectively and safely break thick clods, arches and bridges formed in large concrete and steel silos. It can be used in many industrial facilities such as cement, mine, ceramic, plaster, feed, food.

It is generally designed for large silos. It is a machine that is effective in using the silos continuously at full capacity. In addition, it ensures that the human factor is kept in a safe area during the periodic revision of the silos. For this reason, it can be said that it has been designed in full compliance with OHS requirements.

User Hamster is a fully hydraulic silo cleaning machine. It is used in bulk storage areas that have been many different sizes with open top. The product is an effective system that sweeps the accumulation downwards without the need for individual access to all compartments.

The User hamster is once assembled from a circular center. It descends "like cutting grass" by cleaning the accumulation inside with its destructive effect. Breaker heads are attached to the tip of the whip.

The operator can control the machine independently of the machine thanks to the remote control. Thus, serious accidents are prevented. The solid layer formed in the silo can be safely cleaned from a convenient and convenient point for observation.

It is a faster and safer effective cleaning system compared to existing destructive cleaning methods of silos. Thus, the silo remains passive for a very short time. It minimizes the economic loss caused by time in production.

The system enters the silo with a 2.4 - 8 meter long boom. By creating certain cleaning methods in the inner wall area, it applies hard whip blows to the cloven area. The mass falls down with the effect of gravity. Accident risks are prevented since there are no people in the environment during these operations.

180 degree up and down movement of the boom can easily reach the deposits.In addition, with the ease of mounting the boom with specially designed system, 360 degree cleaning can be achieved in the silo after installation.

The system can be controlled from the most convenient and safe point thanks to radio frequency controls. The disposal of deposits can be done from certain distances of the silo. In addition, the crusher head can be lowered to the desired level through the drum and the deposit layers can be easily reached. All these operations can only be done with a working group of 2 people. Thus, safe cleaning and economic gain are created. It can work for a long time thanks to the hydraulic system cooling unit. There are no pressure losses in the system.

Different tips have been developed for the disposal of solid or soft materials inside the silo. Thus, the effect can be achieved at maximum power according to the hardness degree.

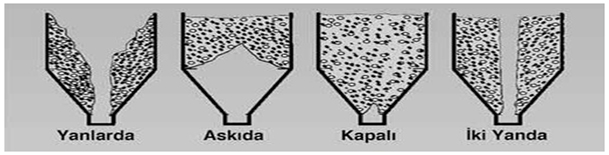

USER HAMSTER is a system where you can safely perform cleaning applications in the above-mentioned material and silo blockage models.

Sonic Application

In smaller diameter silos, discharge can be performed by using the sound pressure effect for the accumulation and clogging of micronized materials on the inner wall and throat. Effective results have been obtained in many materials in the installations made to prevent these occurrences.

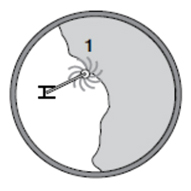

In the picture below, there is a user sonic mounted on the side wall of a lime silo.

Silo diameter is 2 meters and height is 8 meters.

There is a 10 second run period every two hours. With this working period, the above mentioned problems have been solved.

Thus, expensive and dangerous cleaning models was prevented. The silo has been ensure operated at full capacity continuously.